About us

BILLSON STAINLESS PVT LIMITED

BILLSON is a part of SAJJAN Group founded in 1935 and had a very modest Beginning. From day one the objective had been customer satisfaction.

Its a family owned company and run by Professionals with the best experience in the industry. Our team understand the customer requirements very closely and deliver the part in best possible quality and faster lead times.

The company has grown from 7 people to 450 people in total group today and spread is customer base in 23 Different countries. The best part of the BILLSON is that It has got all facilities to manufacture a high quality part in-house.

We are an ISO 9001:2015, AD2000 and PED Certified Organisation by TUV Rheinland. We are environment Friendly Organisations and use Natural Gas for our Heat Treat and Shell firing furnaces, We also have 800 KW if Solar power thus putting all efforts to reduce carbon footprint and Global Warming

Facility

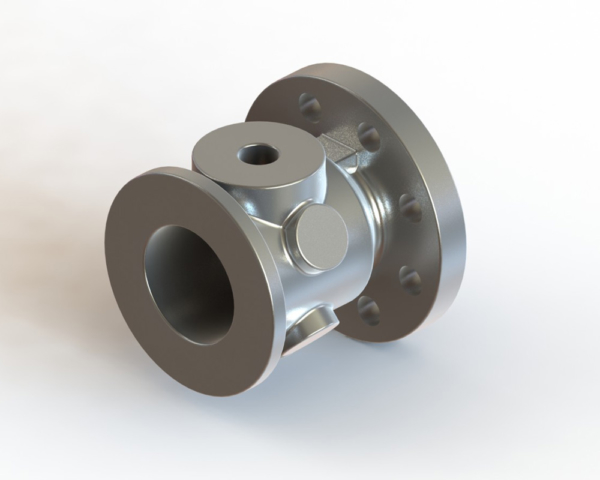

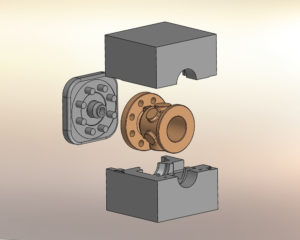

CAD

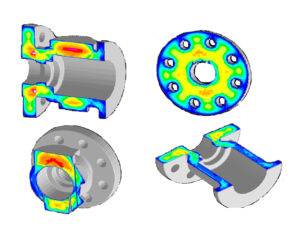

Simulation

Tool Making

Wax Injection

Ceramic Coating

Rainfall Sander

Dewaxing

Pouring

Knock Out

Shot Blasting

Fettling

Heat Treatment

Quality

- Inward raw material analysis by Hand held portable Spectrometer.

- Chemical Analysis by Lab model Spectrometer imported from Germany for all the heats.

- Dimensional Inspection by Digital Vernier Callipers, Height Gauges, Slip Gauges and CMM with scanning from Mitutoyo JAPAN.

- Roughness Test, Mitutoyo.

- Radiography Testing.

- Mechanical Testing, UTS, YS.

- Ultrasonic Testing.

- Liquid Penetrant Testing.

- Magnetic Particle Inspection.

- Metallography Inverted Microscope for Micro Structure with image analyse.

- Short time High Temperature Tension Test Facility.

- Magnetic Permeability Test Facility.

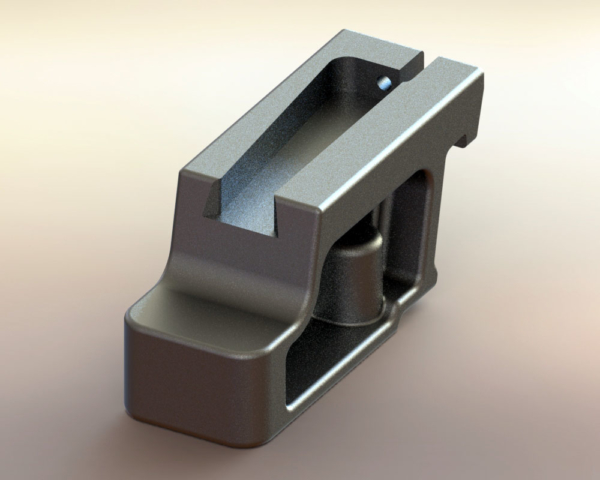

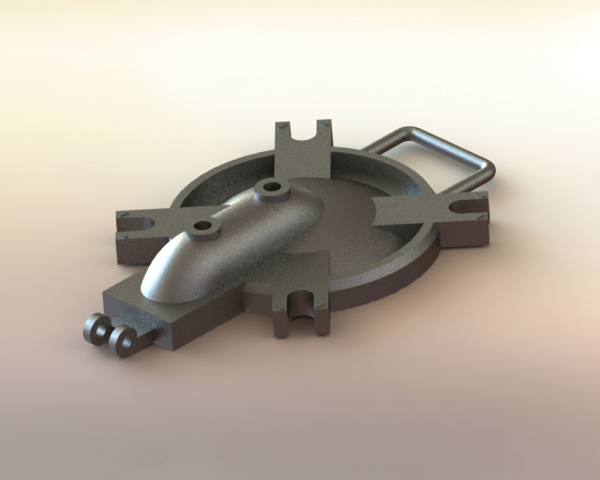

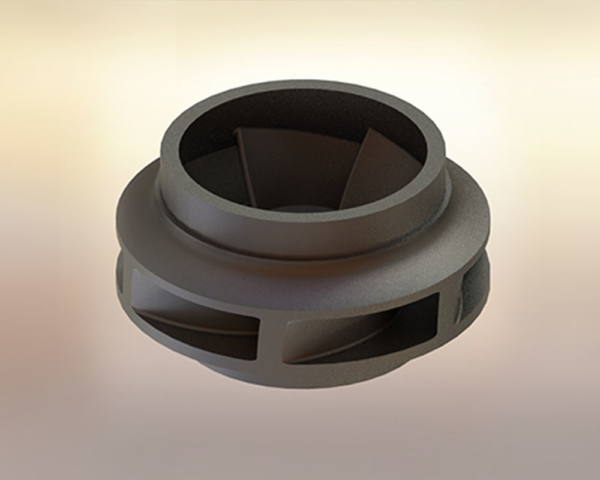

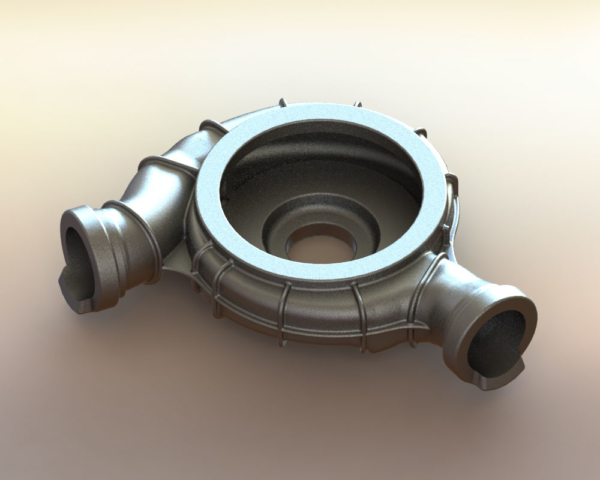

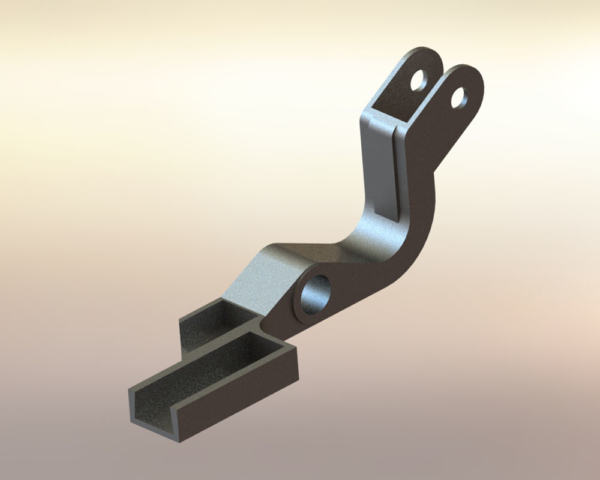

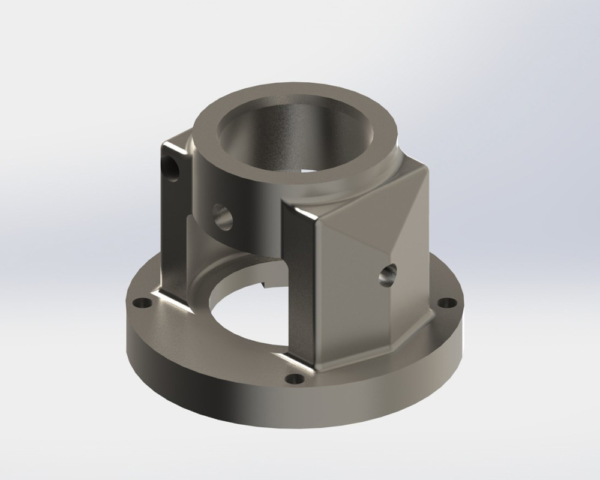

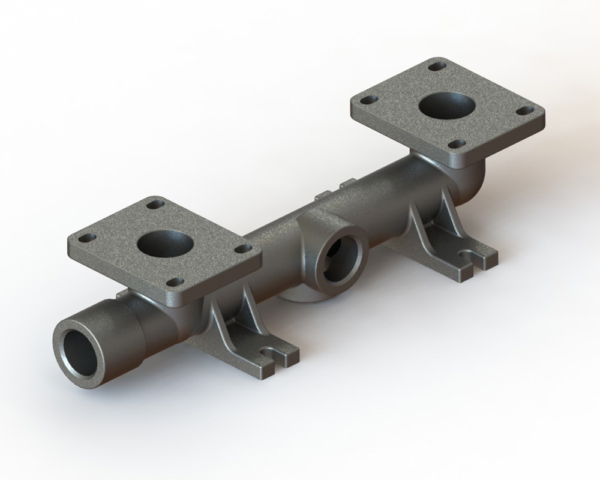

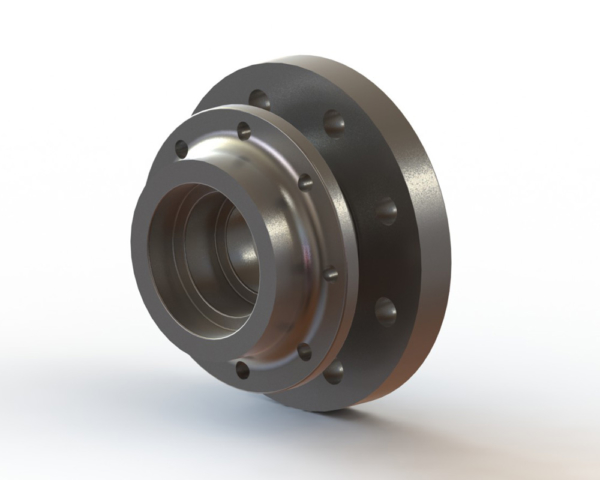

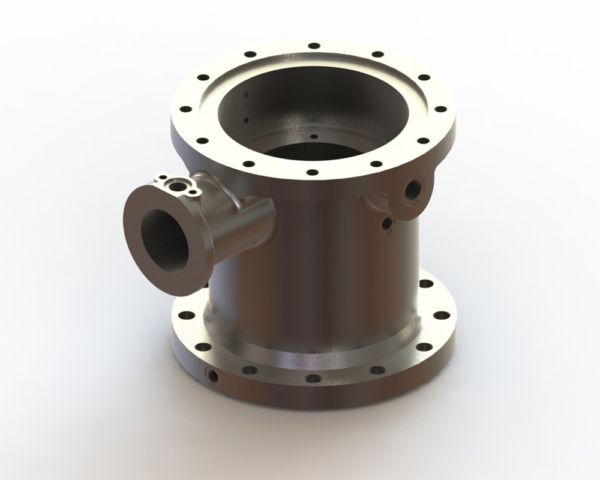

Products

Grades Manufactured

| ASTM | DIN | ASTM | DIN | ||

| Carbon Steel | A216 – WCB | 1.0619 | Austenitic Ferrite Duplex Steels | A351 – CF3MN | 1.4435 |

| A216 – WCC | A351 – CD4MCu | ||||

| A352 – LCC | 1.1138 | A351 – CG6MMN | 1.3964 | ||

| A352 – LCB | A351 – CK3MCuN | ||||

| Low Alloys Steels | A217 – WC1 | 1.5419 | Nickle Based Super Alloys | A494 – M-35-1 | 2.4365 |

| A217 – WC6 | 1.7356 | A494 – M-35-2 | |||

| A217 – C5 | 1.7363 | A494 – N-7M | |||

| Heat Resistant Steel | A297 – HF | 1.4825 | A494 – CY40 | 2.4816 | |

| A297 – HH | 1.4837 | A494 – CW12MW | 2.4686 | ||

| A297 – HI | 1.4846 | A494 – CW6M | |||

| A297 – HK | 1.4848 | A494 – CW2M | 2.461 | ||

| 1.4749 | A494 – CW6MC | 2.4856 | |||

| A297 – HD | 1.4823 | A494 – CX2MW | 2.4602 | ||

| Austenitic Stainless Steel | A351 – CF3 | 1.4306 | A494 – Cu5MCuC | 2.4858 | |

| A351 – CF3M | 1.4404 / 1.4409 | A560 – 50Cr50Ni | |||

| HU | 1.4865 | A560 – 50Cr50Ni-Nb | 2.4813 | ||

| HP | 1.4852 | Cobalt Based Alloys | STELLITE 3 | ||

| A351 – CF8 | 1.4308 | STELLITE 6 | |||

| A351 – CF8M | 1.4408 | ||||

| A351 – CF8C | 1.4827 | ||||

| A351 – CF10 | 1.4308 | ||||

| A351 – CK20 | 1.4843 | ||||

| A351 – CH20 |

Industries Served

BILLSON’s advanced investment cast tooling options ensure the highest quality products which are built to meet various industry specifications and standards. Our unique parts optimization capabilities are particularly important to these sectors and its “zero failure” tolerances. At Billson, process control is preeminent, resulting in more value-added products and services for our customers.

Aerospace

Automotive

Burners

Defense

Electronics

Farm Machinery

Food & Beverage

Industrial

Machine Tool

Medical Tools

Military

Mining

Nuclear

Oil & Gas

Packaging

Petroleum

Power Generation

Pressure Vessel

Pumps

Recreation

Valves

Clients

Linear Tolerances And Measurements

The castings produced by Lost wax process are referred to close tolerance and exact allowance. With our Experience and expertise we can advise you in advance the possible tolerances. It is very common to make expensive tooling to achieve certain dimensions or tolerances which may be achieved with best design practise without going for expensive tooling. To avoid this, We work with our customers to find out the best allowance so that the casting process can be used optimally. TOLERANCES AS PER INTERNATIONAL STANDARD VDG P690 The tolerances of cast parts produced by the Lost wax method have been mentioned and explained in the international standard VDG P690. BILLSON also produces according to this standard, using the degree of accuracy D1 as the standard.

- Accuracy D1: Standard tolerances

- Accuracy D2: Accurate tolerances

- Accuracy D3: Very accurate tolerances that can only be achieved for a limited number of dimensions and / or surfaces.

Global Presence

Phone / Email

+91-9876700476

info@billsonstainless.com

Regd. Office

404, Gill Road, Miller Ganj,

Ludhiana-141003, Punjab,India.

Factory

Village Dharaur, Dehlon Sahnewal Road, Ludhiana-141120, Punjab, India.

How to reach?

Chandigarh (Chandigarh International Airport)

Amritsar (Sri Guru Ram Dass Jee International Airport)

Delhi International Airport (Indira Gandhi International Airport)

Delhi Domestic Airport

Get In Touch

Please use below form:-